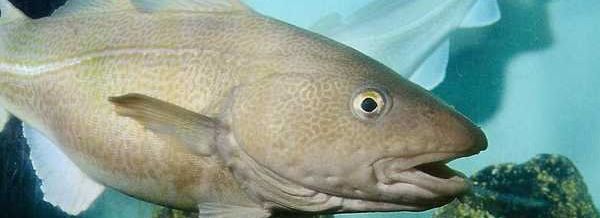

Beautiful Fish - TV shows with more viewers than news

Hugmyndin að þáttunum kviknaði hjá Gunnþórunni Einarsdóttur matvælafræðingi hjá Matís og Brynhildi Pálsdóttur vöruhönnuði. Þættirnir eru sýndir á RÚV á sunnudagskvöldum kl.

Beautiful Fish - TV shows with more viewers than news Nánar »