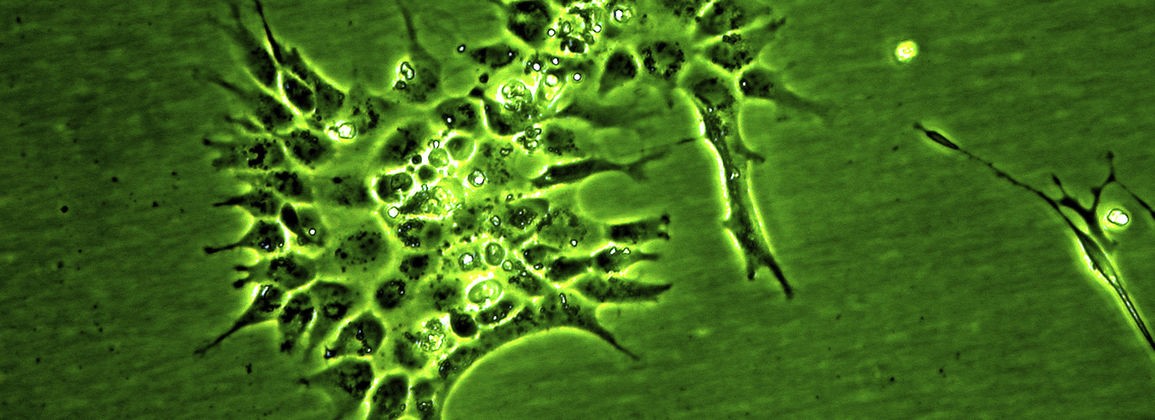

Value creation is the key word - It is important that knowledge becomes a product and values

Hjá Matís er lögð áhersla á hagnýtingu og markaðshugsun í öllum verkefnum og starfsemi fyrirtækisins því skjót útbreiðsla og hagnýting

Value creation is the key word - It is important that knowledge becomes a product and values Nánar »