Lobster Bisque from the Chef - development and marketing

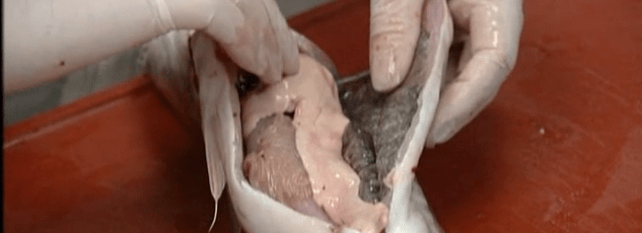

Humarsoð Kokksins vöruþróun og markaðssetning / Lobster Bisque from the Chef – development and marketing Tilgangur verkefnisins var að hefja

Lobster Bisque from the Chef - development and marketing Nánar »